Understand the negative electrode material of lto lithium titanate batteries: Lithium titanate-zero strain material

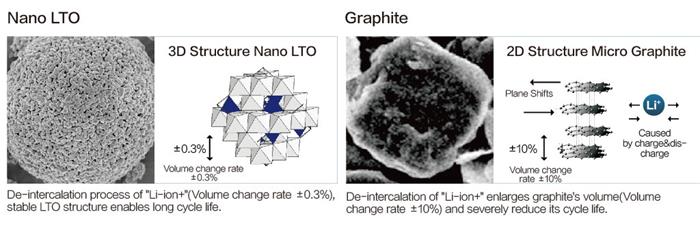

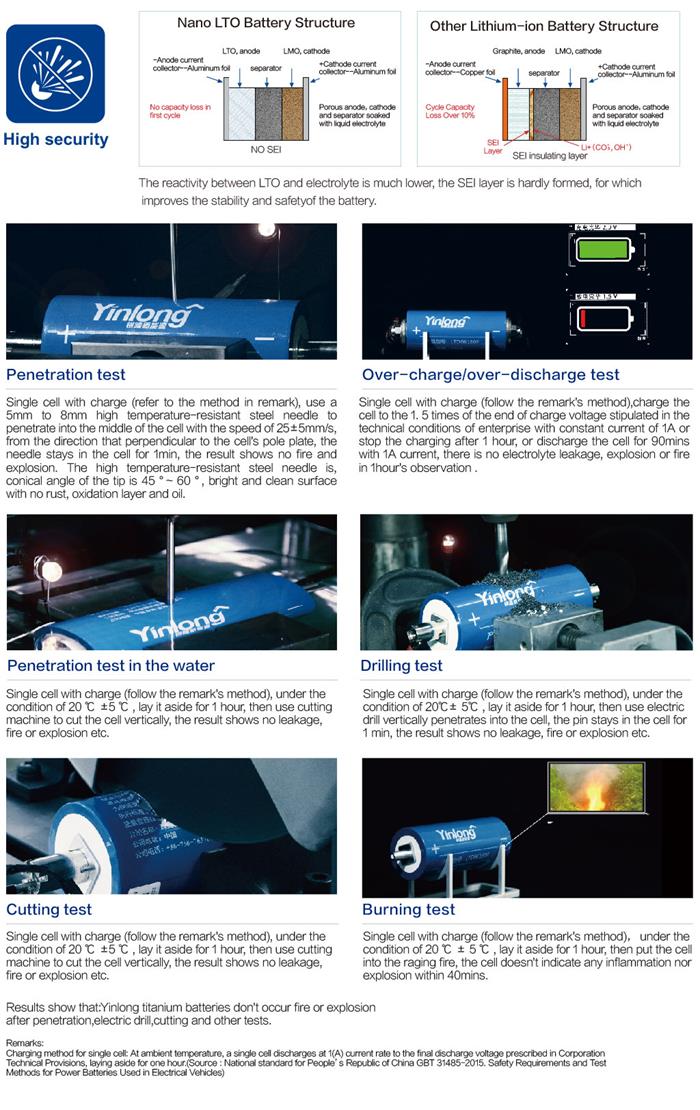

Lithium Titanate (LTO) material has overcome the limitations of the two-dimensional layered structure of graphite electrodes and possesses a stable three-dimensional crystal structure. During the charging and discharging process, the material's structure changes minimally, earning it the designation of "zero-strain material." Compared to graphite anode materials, LTO materials generate almost no thermally unstable SEI (solid electrolyte interphase) layer, thus avoiding the risk of fire or explosion caused by thermal runaway of the SEI layer during decomposition. Although graphite-based anode materials still dominate the lithium-ion battery market, recent research and application of new anode materials have garnered industry attention, with lithium titanate emerging as a particularly important direction. Lithium titanate has several unique advantages over other anode materials, making it a valuable area of research and commercial application for power lithium-ion batteries.

Lithium titanate, with its spinel structure, has a certain capacity to accommodate lithium ions; in simple terms, one lithium titanate can accommodate three lithium ions. The insertion and extraction of lithium ions during charging and discharging have minimal impact on the structure of lithium titanate because its crystal structure changes very little, with the lattice parameter only increasing from 0.836 nm to 0.837 nm. This phenomenon is referred to as "zero strain," which is why lithium titanate is known as a "zero-strain material." Additionally, lithium titanate has a higher electrode potential compared to lithium metal, which prevents the formation of lithium dendrites during overcharging, thus providing better safety and stability. It also features three-dimensional lithium-ion transport channels, enabling high-rate charging and discharging, and can operate across a wide temperature range from -50°C to 60°C.

These properties are crucial for electrode materials as they prevent structural changes during the charging and discharging process due to material expansion and contraction, thereby improving electrode performance, reducing significant capacity degradation, and extending the lifespan of lithium-ion batteries.

Compared to graphite anodes, lithium titanate offers a higher lithium insertion potential, effectively preventing the deposition of metallic lithium and the formation of lithium dendrites. It also possesses much higher thermal stability than graphite, making it less likely to cause thermal runaway in batteries, thus offering greater safety. Additionally, lithium titanate has excellent low-temperature performance, rapid charging capability, and a higher cost-performance ratio, making it promising for applications in large-scale energy storage and other fields.

Several Chinese companies have emerged as key players in the research and development of lithium titanate materials. Notably, Yinlong New Energy is one of the leading companies in domestic lithium titanate material development, owning the world's largest production base for lithium titanate materials. Through the combination of nanomaterial preparation and structural control technologies, they have synthesized high-purity "Yinlong Titanium" materials with unique particle morphology and size design, optimizing the electrochemical performance of lithium titanate materials and solving the dispersion issues of nanomaterials, thus laying a solid technical foundation for Yinlong's lithium titanate batteries.

However, there are still some limitations to the large-scale application of lithium titanate, primarily due to issues related to the material and device aspects:

1. The electronic and ionic conductivities of lithium titanate are 10-13S.cm-1 and 10-9-10-13cm2.s-1, respectively, with an electronic band gap of approximately 2eV, which significantly limits its high-current rate performance due to its inherent insulating properties.

2. Lithium-ion batteries with lithium titanate anodes commonly exhibit a "gassing" phenomenon during charge and discharge cycles and storage, with gas formation being particularly severe at high temperatures.

Despite being recognized as one of the most promising lithium-ion battery anode materials, the intrinsic low electronic conductivity of lithium titanate limits its high-rate performance. Additionally, side reactions between lithium titanate and the electrolyte can lead to gassing issues, hindering the commercial application of lithium titanate.

As research on lithium titanate anode materials continues, lithium-ion batteries using lithium titanate are gradually becoming practical. Modified lithium titanate with carbon materials exhibits better rate capabilities and surface chemical properties, along with its inherent low-temperature performance, exceptionally high cycle life, and safety. It is expected to find further applications in hybrid vehicles, flexible electronic devices, and large-scale energy storage.

In addition to its safety and lifespan advantages, charging speed is also a crucial factor in large-scale energy storage. Data shows that while traditional lithium-ion batteries with the same capacity require 2-4 hours to charge, lithium titanate batteries(lto battery) only need 6 minutes, which is considered highly valuable for peak shaving. The high-rate performance of lithium titanate can provide a minimal high-rate system for users, offering peak shaving and auxiliary services with rapid input/output capability.

The high stability and long life cycle of lithium titanate make it significantly superior to traditional lithium-ion batteries, offering unique advantages in energy storage applications. It is highly suitable for large-scale energy storage and is regarded as "one of the most promising energy storage batteries."

Currently, the main issues with lithium titanate include its lower rate performance and insufficient energy density. However, the fast-charging advantage of lithium titanate batteries, combined with widespread charging infrastructure, reduces the energy density requirements for electric vehicles equipped with lithium titanate batteries. In the rapidly growing electric vehicle industry, advancing lithium titanate power lithium-ion battery technology and expanding its applications require collective efforts from all stakeholders.