UN 38.3 Compliance for Lithium Batteries: Essential Tests and Safety Standards

Lithium batteries power 83% of portable electronics worldwide, but improper handling during transportation accounts for 23% of aviation fire incidents. To prevent these risks, it's essential to follow the UN 38.3 standard for shipping lithium batteries via air, road, or rail. This standard ensures the safety of lithium batteries during transit and outlines eight critical tests that must be met to guarantee compliance.

1. Altitude Simulation Test

This test simulates the conditions in an aircraft cargo hold at altitudes of up to 15,000 meters. The battery undergoes exposure to a low air pressure of 11.6 kilopascals for six hours. To pass, the battery must show no loss of mass, maintain the closure of the overpressure valve, remain free from cracks or leaks, and exhibit no more than a 10% deviation in voltage from its initial value.

2. Thermal Test

Following the altitude simulation, the battery undergoes a thermal test. First, it is stored for six hours at 72°C and then cooled to -40°C for the next six hours. This extreme temperature fluctuation helps evaluate the pressure on seals and internal electrical connections. After 10 cycles in a thermal shock chamber, the battery is stored at room temperature for 24 hours. To pass, it must meet the criteria outlined in the altitude simulation.

3. Vibration Test

The vibration test simulates the typical shaking a battery experiences during transport. The battery is placed in a device that shakes between 7 and 200 times per second (Hertz) for a total of three hours. The same criteria from the altitude simulation must be met, ensuring the battery's durability against physical impact during transit.

4. Impact Test

The impact test assesses how a lithium battery reacts when subjected to force. Depending on the battery's type and size, force levels of 150G/6mS or 50G/11mS are applied. The housing must remain intact without any cracks or damage. Like the previous tests, it must meet the conditions specified in the altitude simulation.

5. External Short Circuit Test

In this test, the battery is heated to 57±4°C and then subjected to an external short circuit. The battery temperature must not exceed 170°C during the test, and it should cool back down to 57°C within 60 minutes. The housing must remain undamaged for up to six hours after the test.

6. Crush Test

Only cells are subjected to the crush test, which simulates external damage such as impacts in a car crash. A stamping machine is used to apply force to the cells, potentially causing an internal short circuit. To pass, the battery must maintain a housing temperature below 170°C and show no cracks or signs of overheating up to six hours after the test.

| Test | Impact | Crush |

Application | All batteries | Cells only |

Force Profile | 150Gn/6ms (small) or 50Gn/11ms (large) | 9.1kg drop from 61cm or 13kN crush |

Key Metric | Voltage retention ≥90% | Case temp <170°C post-damage |

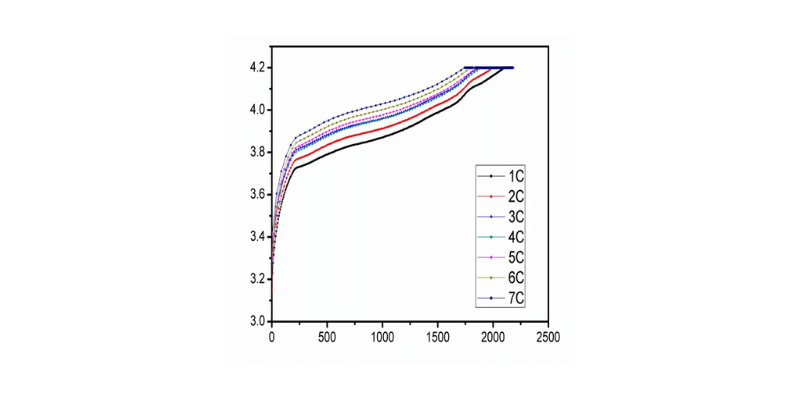

7. Overcharging Test

Lithium batteries are also tested for overcharging. For 24 hours, twice the maximum permissible charging current is applied. The battery must function without malfunction, and after the test, it is stored safely for seven days.

8. Fast Discharge Test

The fast discharge test ensures the battery’s safety during rapid discharge. The battery is subjected to a current exceeding the permitted maximum several times. It must pass the test without damage to the battery.

UN38.3 Certification Validity

UN38.3 certification is valid for one calendar year, expiring on December 31st. After expiration, it can be renewed for an additional year. For example, a certificate issued on December 19th, 2024, will be valid only until December 31st, 2024. A new certificate issued on January 1st, 2025, will be valid until December 31st, 2025.

Packaging Requirements for Multiple Shipping Methods

Each UN38.3 certificate is valid for only one shipping method. Lithium batteries can be shipped using three methods:

· 965: Battery shipped alone

· 966: Battery packed with equipment

· 967: Battery built into the device and not easily removable