Designing High-Performance Custom Battery Pack Enclosures: What Factors Should be Considered?

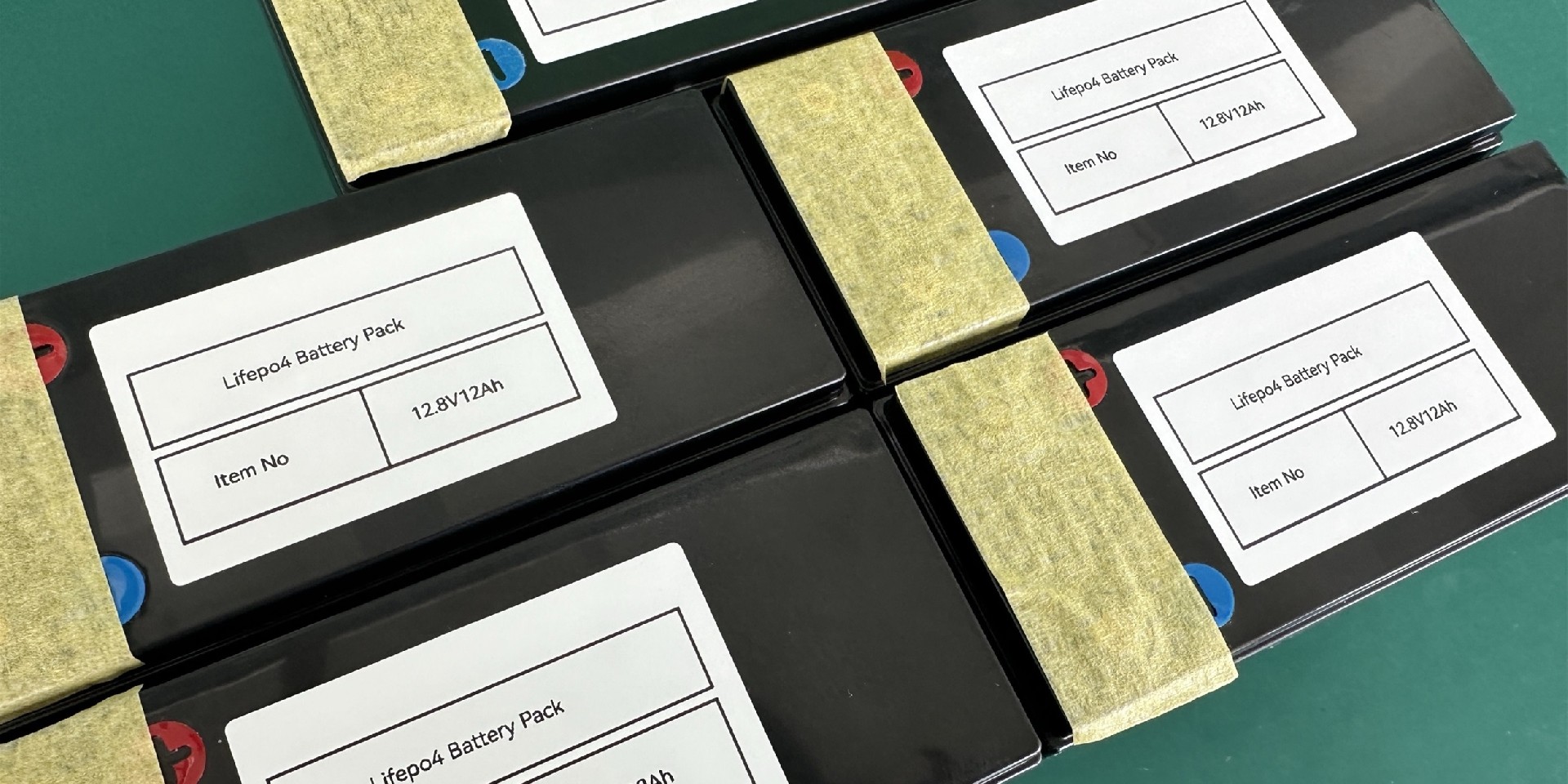

When developing custom battery packs—especially custom lithium battery packs and custom lithium-ion battery packs—the enclosure plays a critical role in performance, safety, and marketability. Whether for EVs, energy storage, or portable electronics, a well-designed plastic enclosure ensures durability, compliance, and brand alignment. Below are the essential factors to consider.

1. Compliance & Certification: Meeting Industry Standards

Regulatory compliance ensures the safe transport and operation of custom lithium-ion battery packs. Meeting certifications like UN 38.3 prevents legal issues and enhances market acceptance.

Regulatory compliance is non-negotiable for custom lithium-ion battery packs. Key considerations include:

· UN 38.3 Certification – Mandatory for lithium battery transportation, covering vibration, thermal, and crush tests.

· Drop & Impact Resistance – Enclosures must protect cells from mechanical stress.

· Thermal & Fire Safety – Flame-retardant materials may be required for high-risk applications.

Working with an experienced manufacturer early in the design phase ensures compliance, avoiding costly redesigns later.

2. Material Selection: Balancing Durability & Cost

The right plastic material impacts performance in extreme conditions. Choosing between ABS, PC, or nylon affects cost, weight, and environmental resistance.

The right plastic material depends on the operating environment:

· ABS – Cost-effective but brittle in extreme cold.

· Polycarbonate (PC) – High impact resistance, ideal for rugged applications.

· PC/ABS Blends – Combines strength and thermal stability.

· Nylon (PA6, PA66) – Excellent chemical and abrasion resistance.

For custom lithium battery packs exposed to UV, moisture, or extreme temperatures, material selection is crucial for longevity.

3. Structural Integrity: Securing Internal Components

Proper internal support prevents cell damage from shocks and vibrations. Foam padding, ribbed designs, and modular compartments enhance reliability.

A well-designed enclosure prevents internal movement, which can damage battery cells. Solutions include:

· Foam Padding / RTV Silicone – Absorbs shocks and vibrations.

· Ribbed Internal Structures – Locks components in place without adhesives.

· Modular Compartments – Simplifies assembly and maintenance.

4. Sealing Methods: Protecting Against Environmental Factors

Effective sealing prevents moisture and dust ingress. Ultrasonic welding, gaskets, and mechanical fasteners offer different levels of protection and accessibility.

Moisture and dust ingress can degrade custom battery packs. Common sealing techniques:

· Ultrasonic Welding – Fast, glue-free bonding for high-volume production.

· Mechanical Fasteners (Screws/Bolts) – Allows easy servicing but may require tamper-proofing.

· Gaskets & Adhesives – Best for low-volume or waterproof applications.

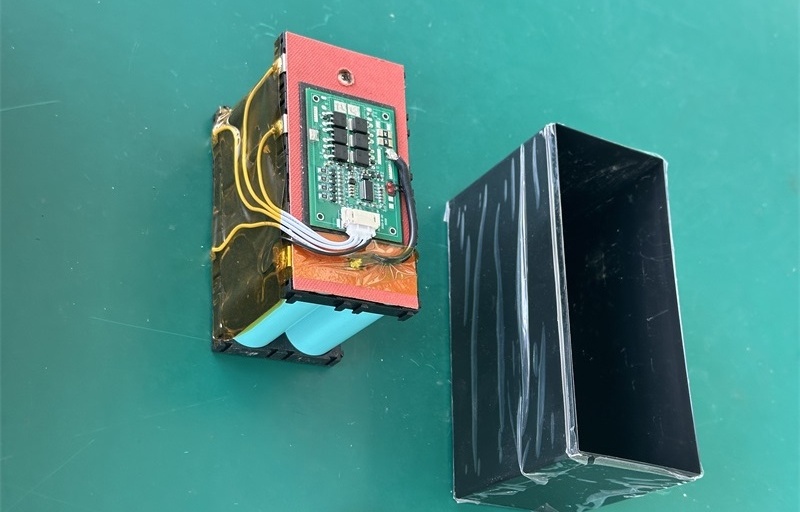

5. Thermal Management & Safety Circuits

Heat dissipation and BMS integration prevent overheating in custom lithium-ion battery packs. Proper thermal design extends lifespan and prevents failures.

Custom lithium-ion battery packs generate heat, requiring:

· Ventilation & Heat Dissipation – Passive cooling via vents or active cooling with fans.

· Integrated BMS (Battery Management System) – Prevents overcharging, overheating, and cell imbalance.

· Fire-Retardant Barriers – Critical for high-energy-density packs.

6. Branding & Aesthetic Customisation

Custom logos, textures, and finishes enhance brand recognition while maintaining functionality. Laser etching and digital printing offer durable branding solutions.

A custom battery pack enclosure should reflect brand identity while maintaining functionality:

· Laser Etching – Permanent logos, warnings, or serial numbers.

· Digital Printing – Full-colour branding without compromising structural integrity.

· Custom Textures & Finishes – Enhances grip and visual appeal.

7. Upgrading Legacy Designs

Transitioning to custom lithium battery packs may require enclosure redesigns. Reverse engineering helps optimize space and improve performance efficiently.

Many manufacturers transition from older battery chemistries to custom lithium battery packs, requiring:

· Cell Format Adaptation – Prismatic, cylindrical, or pouch cell compatibility.

· Space Optimisation – Redesigning enclosures for higher energy density.

· Reverse Engineering – Replicating existing designs with improved materials.

Final Thoughts

Designing custom battery pack enclosures demands a balance of engineering precision, regulatory compliance, and brand aesthetics. By prioritising material selection, safety features, and manufacturability, we can develop high-performance custom lithium-ion battery packs that meet industry demands.

As an experienced customised lithium battery manufacturer, Energyx ensures a seamless process from CAD prototype design to mass production, providing you with reliable and personalised battery solutions! Contact us now to get a quote!